By Xinyu Zhang*

Functional nanocomposites are composed with different combinations from a large selection of nanomaterials, such as nanocarbons, metal oxides/chalcogenides, carbides, phosphides, polymers, etc., which possess superior mechanical, thermal and electrical properties, leading to broad applications in smart structures, chemical sensors, energy storage and nano-electronic devices. However, the high cost and difficulty in getting large scale, high quality nanocomposites remain challenges.

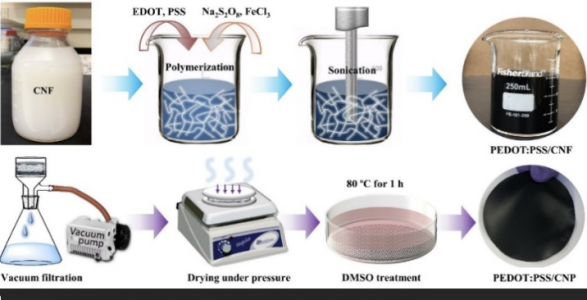

Figure 1: Schematic Illustration of the preparation of PEDOT:PSS/CNF and the fabrication of PEDOT:PSS/CNP (Ref: Chem. Eng. J. 428 (2022) 131994

Zhang Research Group has been dedicated to develop facile, reliable, sustainable manufacturing technologies towards functional nanocomposites for energy related applications. For example, manufacturing of transition metal chalcogenides (MCs) on graphene support (MC-Gr) was developed based a one-step microwave approach. In this regard, a series of suitable combinations of metals and chalcogens have been selected, such as molybdenum disulfide (MoS2), molybdenum ditelluride (MoTe2), molybdenum sulftotelluride (MoSTe), cobalt doped MoS2 (Co-MoS2) and other hybrids. Electrochemical characterizations i.e., cyclic voltammogram (CV), galvanostatic charge-discharge (GCD), electrochemical impedance spectroscopy (EIS) and so on, reveal that the as-produced nanocomposites can be used as high mileage catalyst materials for hydrogen evolution reaction (HER) and electrical energy storage (EES) such as hybrid-capacitor applications.

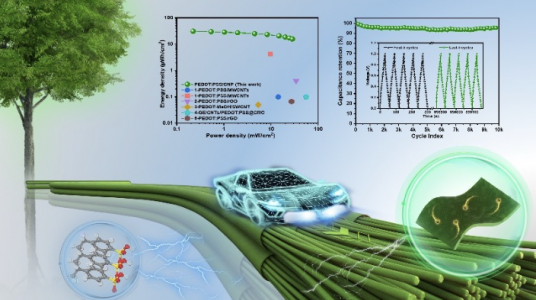

Figure 2: Schematic illustration of energy storage applications of the functional nanocomposites (Ref: Chem. Eng. J. 428 (2022) 131994)

Cellulose nanofibrils (CNF) have emerged as promising nanomaterials with great application potential in diverse fields, in light of their outstanding physiochemical properties such as superior mechanical strength, large specific surface area, high aspect ratio, tunable surface chemistry, along with renewability and biodegradability. Due to the presence of abundant hydroxyl groups on the surface and the semi-crystalline structure, CNF exhibit remarkable tendency to form mechanically stable nanostructures (e.g., films, foams). Thus, CNF have been widely used as building blocks to be compounded with various active materials for the preparation of flexible electrodes for energy storage devices.

Zhang research group demonstrated a flexible nanocomposite, developed based on cellulose nanofiber-conducting polymer system (CNF-CP). As illustrated in Figure 1, Formic acid was used to hydrolyze paper mill sludge, a waste from paper industries, resulted in high quality CNF, which is used as support for conducting polymers. The conducting polymers were in-situ deposited to the CNF surface, and CNF-CP free standing paper was formed through simple filtration process, which possesses outstanding flexibilities and energy storage properties. More development is on the way to develop large scale sustainable production of the functional nanocomposites, towards energy applications (Figure 2).

Xinyu Zhang serves as a Professor in the Department of Chemical Engineering and is the recipient of the Sustainability Professional Development Sponsorship Award.

Learn about the SDGs & AU and our contributions related to this post.